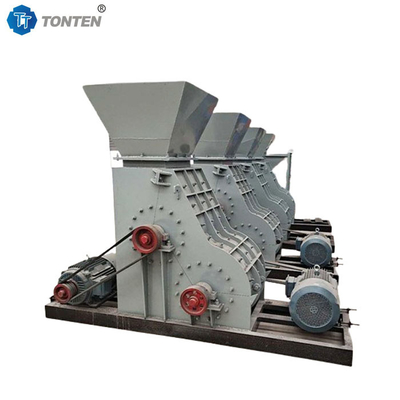

Double Stage Hammer Crusher Machine Shale Pebbles Crusher Fine Powder

Product Details:

| Place of Origin: | China |

| Brand Name: | TONTEN |

| Model Number: | TT-DH1200x1400 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 Set |

|---|---|

| Price: | Negotiable |

| Packaging Details: | standard international export packing, container or as required |

| Delivery Time: | 5-7 working days |

| Payment Terms: | T/T |

| Supply Ability: | 50 Sets per month |

|

Detail Information |

|||

| Yield: | 100-160t/h | Power: | 90+132kw |

|---|---|---|---|

| Maximum Feed Size: | 220mm | Discharge Port Adjustment Range: | 1-3mm |

| Length X Width X Height: | 5800x2658x3260mm | Item: | Double Stage Hammer Crusher Machine |

| Application: | Shale Pebbles | Output Material: | Fine Powder |

| Highlight: | double stage hammer crusher machine,shale pebbles crusher machine,fine powder crusher machine |

||

Product Description

Double Stage Hammer Crusher Machine Shale Pebbles Crusher Fine Powder

Working principle:

The TONTEN machinery double stage hammer crusher machine adopts a design that combines mechanical and airflow pulverization methods. First, the material enters the mechanical pulverization chamber and is initially crushed under the action of the high-speed rotating rotor. Then, the crushed material is sucked into the pulverization chamber by the airflow, and further ground under the action of the violent airflow to finally reach the required particle size. The whole process does not require a screen, which greatly improves the pulverization efficiency.

Applicable materials:

The two-stage screenless bottom pulverizer is suitable for crushing raw materials in various minerals, chemicals, building materials and other fields, such as limestone, quartz sand, carbon black, ceramic raw materials and other hard and brittle materials, and processes materials with high water content or high viscosity, such as dolomite, coal gangue, slag, construction waste, shale, fermented feed, organic fertilizer raw materials, bentonite, cement, clay, and other similar wet materials.

Double stage hammer crusher machine advantages:

1. Double stage hammer crusher machine suitable for continuous production, can realize automatic operation, and reduce labor costs.

2. By adjusting the rotor speed, the particle size distribution can be flexibly controlled. Because the two-stage screenless bottom pulverizer has a screenless grate bottom design inside, the hammer head is less worn, which reduces maintenance costs.

3. Crusher machine don't need for screen, avoiding the problem of affecting production due to screen blockage. Improves the adaptability and work efficiency of the equipment to high-humidity materials.

![]()

![]()

Double stage hammer crusher machine parameter:

|

Model |

Maximum feed size (mm) |

Discharge adjustment range (mm) |

Capacity(t/h) |

Motor power(kw) |

Length x width x height(mm) |

|

TT-DH400x600 |

≤120 |

1-3 |

15-25 |

18.5+22 |

2350x980x1400 |

|

TT-DH600x600 |

≤120 |

1-3 |

20-35 |

22+30 |

3200x1200x1800 |

|

TT-DH600x800 |

≤150 |

1-3 |

30-50 |

37+45 |

3500x1600x1950 |

|

TT-DH800x800 |

≤150 |

1-3 |

50-65 |

45+55 |

3810x1780x2200 |

|

TT-DH800x1000 |

≤180 |

1-3 |

60-80 |

55+75 |

4100x1900x2360 |

|

TT-DH1000x1000 |

≤180 |

1-3 |

65-100 |

75+75 |

4200x2100x2560 |

|

TT-DH1000x1200 |

≤200 |

1-3 |

80-120 |

75+90 |

4800x2530x2600 |

![]()