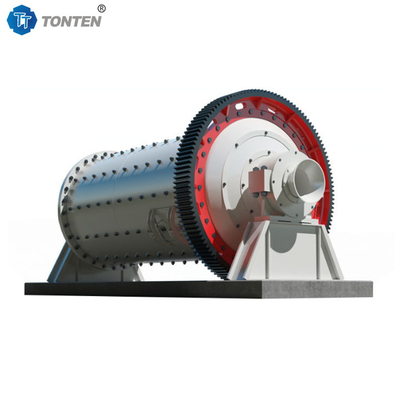

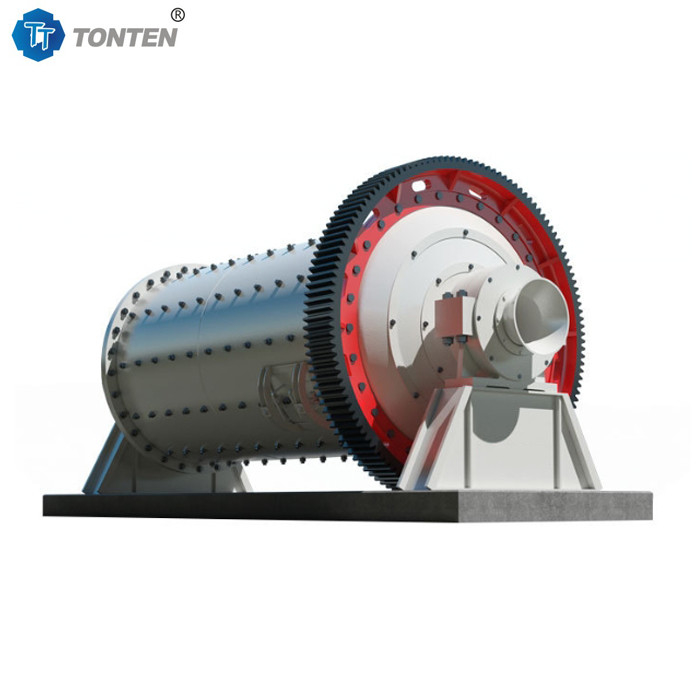

Bauxite Ball Grinding Mill Marble Limestone Gold Ball Mill In Singapore

Product Details:

| Place of Origin: | China |

| Brand Name: | TONTEN |

| Model Number: | BM-1200x3000 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 Set |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Export wooden packing or in container |

| Delivery Time: | 7-10 work days |

| Payment Terms: | T/T |

| Supply Ability: | 30 Sets per month |

|

Detail Information |

|||

| Grinding Method: | Wet And Dry Use | Simplified Speed: | 15r/min |

|---|---|---|---|

| Ore Discharge Method: | Overflow Type Bauxite Ball Grinding Mill | Supply Voltage: | 220/380/440V |

| Output: | 95-110t (depending On Process Conditions) | Discharge Size: | 0.4mm |

| Applicable Areas: | Ore Dressing, Metallurgy, Crushing | Effective Volume: | 200m³ |

| Highlight: | bauxite ball grinding mill,limestone gold ball mill,marble ball mill with warranty |

||

Product Description

Bauxite Ball Grinding Mill Marble Limestone Gold Ball Mill In Singapore

Working Principle:

TONTEN ball mills are used for crushing and grinding materials such as bauxite and marble. Gold ball mills are widely used in the mining and metallurgical industries, particularly in gold extraction and processing, where they have become indispensable equipment. The use of highly wear-resistant materials reduces maintenance requirements and lowers long-term operating costs. Their operating principle is based on the collision and friction between the grinding balls and the ore. The ball mill is equipped with multiple grinding balls. When the mill is running, the grinding balls move along a circular path within the cylinder, violently colliding with the ore and grinding it to the desired fineness. Bauxite enters the ball mill through the feeder, where the ore and grinding balls interact within the cylinder, causing grinding. The ground material passes through a classifier to separate qualified and unqualified material. Qualified material is discharged through the discharge port for further processing.

Ball Mill Features:

1. High Efficiency: Through rational design and optimized ball configuration, grinding efficiency is significantly improved.

2. High Wear Resistance: The cylinder and grinding balls are made of wear-resistant materials, extending their service life.

3. Adjustable Particle Size: By adjusting the size and number of grinding balls, the final product particle size can be precisely controlled.

4. Versatility: A wide range of materials, including varying particle sizes and hardnesses, can be processed.

5. Easy Operation: The TONTE ball mill is relatively simple to operate and maintain, making it suitable for large-scale production.

6. Energy Saving and Environmental Protection: The new ball mill utilizes energy-saving technology, reducing energy consumption and environmental pollution.

7. Low Energy Consumption: The new ball mill utilizes energy-saving technology, reducing energy consumption.

8. Good Sealing: Prevents material and dust leakage, maintaining a clean working environment.

9. Continuous Operation Capability: Suitable for large-scale continuous production.

![]()

Ball Mill Grinding Machine Parameters:

|

Items |

Simplified speed |

Ball load(t) | Feeding size(mm) | Discharging size(mm) | Capacity(t/h) | Power(kw) | Weght(t) | ||||

| BM900x1800 | 36-38 | 1.5 |

≤20 |

0.075-0.89 | 0.65-2.5 | 18.5 | 5.8 | ||||

| BM900x3000 | 36 | 2.7 | ≤20 | 0.075-0.89 | 1.1-3.5 | 22 | 6.95 | ||||

| BM1200x2400 | 36 | 3 | ≤25 | 0.075-0.6 | 1.5-4.8 | 30 | 13.56 | ||||

| BM1200x3000 | 36 | 3.5 | ≤25 | 0.074-0.4 | 1.6-5 | 37 | 14.31 | ||||

| BM1200x4500 | 32.4 | 5.2 | ≤25 | 0.074-0.4 | 1.6-5.8 | 55 | 15.6 | ||||

| BM1500x3000 | 29.7 | 7.5 | ≤25 | 0.074-0.4 | 2-5 | 75 | 19.5 | ||||

| BM1500x4500 | 27 | 11 | ≤25 | 0.074-0.4 | 3-6 | 110 |

22.1 |

||||

| BM1500x5700 | 28 | 12 | ≤25 | 0.074-0.4 | 3.5-6 | 130 | 25.8 | ||||

| BM1830x3000 | 25.4 | 11 | ≤25 | 0.074-0.4 | 4-10 | 130 | 34.5 | ||||

| BM1830x4500 | 25.4 | 15 | ≤25 | 0.074-0.4 | 4.5-12 | 155 | 38 | ||||

| BM1830x6400 | 24.1 | 21 | ≤25 | 0.074-0.4 | 6.5-15 | 210 | 43 | ||||

| BM1830x7000 | 24.1 | 25 | ≤25 | 0.074-0.4 | 7.5-17 | 245 | 43.8 | ||||

| BM2100x3000 | 23.5 | 16 | ≤25 | 0.074-0.4 | 6.5-36 | 155 | 45 | ||||