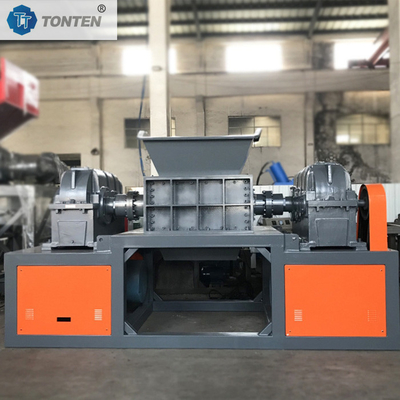

Woven Bag Double Shaft Shredder Shredding Old Cloth Wood Machine

Product Details:

| Place of Origin: | China |

| Brand Name: | TONTEN |

| Model Number: | TT-S1000 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 Set |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Small models are packed in wooden boxes, large models load in containers |

| Delivery Time: | 7-10 work days |

| Payment Terms: | T/T |

| Supply Ability: | 20 sets per month |

|

Detail Information |

|||

| Motor Power: | 30kw | Number Of Shredder Blades: | 20 Pieces |

|---|---|---|---|

| Feed Port Size: | 1000x800mm | Body Material: | Carbon Steel |

| Drive Mode: | Dual Motor Drive | Applicable Materials: | Woven Bag Old Cloth Wood |

| Dimensions: | 3000 X 2000 X 2000 Mm | Model Name: | Double Shaft Shredder Shredding |

| Highlight: | woven bag shredding machine,double shaft cloth shredder,wood shredding crusher machine |

||

Product Description

Woven Bag Double Shaft Shredder Shredding Old Cloth Wood Machine

Structural Features:

Dual-Shaft Design: Utilizing two parallel rotating shafts, a dual-shaft shredder provides more uniform shredding, reducing material clogging and stagnation.

Blade System: Equipped with multiple shredder blades, typically made of high-alloy steel for high strength and wear resistance. The rational arrangement of the blades ensures effective shredding of a wide variety of materials.

Body Structure: The body is typically constructed of heavy-duty carbon steel, ensuring stability and durability under high loads.

Power System: Dual-shaft shredders are equipped with dual motors, providing powerful power and ensuring efficient and fast shredding.

Feed Inlet: The wide feed inlet, typically measuring 1000 x 800 mm, facilitates material input and accommodates a wide variety of materials.

Control System: Dual-shaft shredders are equipped with a PLC automatic control system, enabling automated operation and enhancing user convenience and safety.

Cooling System: Air or water cooling is used to prevent damage from overheating during extended operation.

Safety: Multiple safety features ensure operator safety.

Workflow:

Material Preparation: Place the material to be shredded into the feed port, ensuring that the material size is suitable for the machine.

Starting the Machine: Start the motor, the machine begins operation, and the dual shafts begin rotating.

Shredding Process: The material enters the shredding chamber of the dual shaft shredder, where the dual shaft blades tear and shear the material, gradually breaking it into smaller pieces.

Material Discharge: The shredded material is discharged through the discharge port, typically for further processing on a conveyor belt or other equipment.

Monitoring and Adjustment: The operator can monitor the machine status through the control panel and perform adjustments and maintenance as necessary.

Cleaning and Maintenance: Regularly clean and maintain the dual shaft shredder to ensure long-term stable operation.

Double shaft shredder specification:

|

Model type |

Dimension size(mm) |

Feed size(mm) |

Blads(mm) |

Motor power(kw) |

Weight(kg) |

|

TT-S600 |

2300x1500x1620 |

600X460 |

200 |

11×2 |

1580 |

|

TT-S800 |

2820×1600×2050 |

800X720 |

260 |

15×2 |

3500 |

|

TT-S1000 |

3300×1900×2200 |

1000×800 |

300 |

22×2 |

5000 |

|

TT-S1200 |

3500×2000×2500 |

1200×980 |

320 |

30×2 |

6200 |

|

TT-S1500 |

4100×2260×2800 |

1500×1000 |

550 |

55×2 |

7000 |

|

TT-S1600 |

5800×2400×3300 |

1800×1206 |

560 |

75×2 |

7500 |

|

TT-S1800 |

6100×2700×3500 |

2000×1490 |

600 |

90×2 |

8900 |

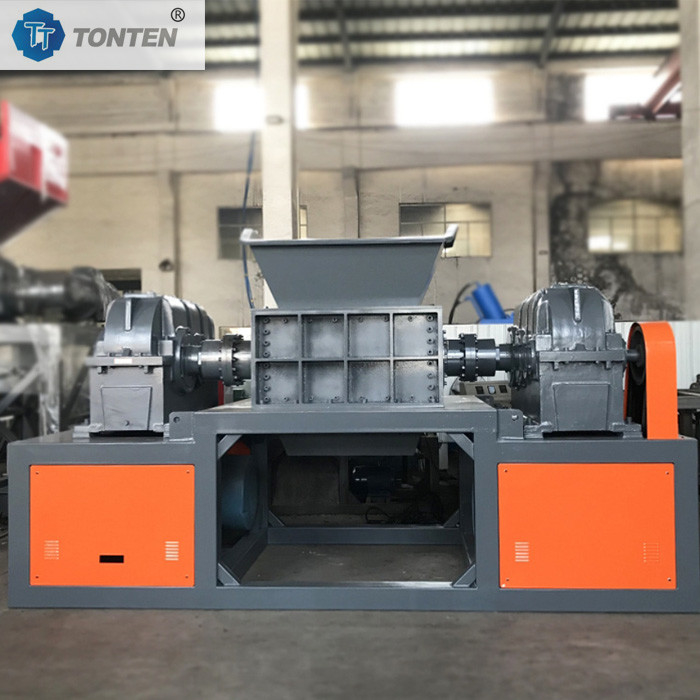

Shredder machine workshop:

![]()