PA PVC PET Plastic Recycling Plant Electrostatic Separator OEM

Product Details:

| Place of Origin: | China |

| Brand Name: | TONTEN |

| Model Number: | TT-E800 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 Set |

|---|---|

| Price: | Negotiable |

| Packaging Details: | standard international export packing, container or as required |

| Delivery Time: | 7-10work days |

| Payment Terms: | T/T |

| Supply Ability: | 30 Sets per month |

|

Detail Information |

|||

| Name: | Electrostatic Separator | Power: | 72kw |

|---|---|---|---|

| Capacity: | 800-1000kg/h | Direct Current High Tension Generator: | 60 Kv/50 MA |

| Power Supply: | Three Phase Four Wire | Static Pressure: | 8-10KV |

| Rotate Speed: | 0-500r/min | Magnetic Roller Number: | 2 Roller. 3 Rollers , 4 Rollers ,6 Rollers |

| Highlight: | PVC plastic recycling plant,plastic recycling plant Electrostatic Separator,OEM pvc recycling plant |

||

Product Description

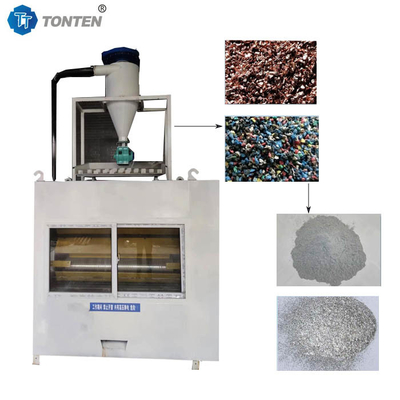

Plastic Electrostatic Separator PVC PET Electrostatic Separator High-Voltage

Product introduction:

Plastic electrostatic separator, also called electrostatic separator, is a device used to separate mixed waste plastic materials and is commonly used in the field of plastic recycling. Plastic electrostatic separator can separate plastics of different materials and is commonly used for separation of plastic waste, home appliance shell crushing materials, electric vehicle crushing materials, toy crushing materials and other plastic waste ABS/PS/sinking PP/flame retardant ABS/flame retardant PS, PET, PVC, PA, PE, PA.

![]()

Features of electrostatic separator:

1. Low plastic separation cost.

2. Electrostatic separator replaces traditional manual sorting methods to increase the speed and quality of sorting.

3. Electrostatic separator intelligent operating system, simple and efficient.

4. Pure physical sorting mode, no three wastes.

5. High compatibility, electrostatic separator can separate and sort all common plastic materials.

6. High degree of automation, to achieve the feeding, heating, speed adjustment, high-pressure discharge

7. Good protection design, safe and convenient operation.

Working principle:

The materials to be sorted enter the high-voltage electrostatic separator. The particles between the positive and negative electric fields are different. With the addition of high-voltage electricity, the copper and plastic particles can be completely separated. It can be used with cable granulators, waste circuit board recycling machines, aluminum-plastic separators, mixed plastic separators, etc. The sorting rate can reach 99.99%. Through special devices, the corresponding charges are generated under the collision and friction of themselves, because different plastics will carry different charges in the high-voltage electric field.

Electrostatic separator specification:

|

Model |

TT-E800 |

TT-E1000 |

TT-E1500 |

|

Voltage |

60000 |

60000 |

60000 |

|

Magnetic roller number |

2 roller. 3 rollers , 4 rollers ,6 rollers optional |

||

|

Feeding size |

20 mesh-280 mesh |

||

|

Capacity |

800-3000 kg/h |

||

|

Rotating motor |

each roller with 1.1 kw motor |

||

|

Material heater |

2 rollers, 3 rollers high temperature 12 kw,low temperature 4 kw 4 rollers,6 rollers high temperature 22 kw,low temperature 8 kw |

||

|

Mineral divide drum heater |

1 kw |

||

|

direct current high tension generator |

0-60KV |

||

|

Power supply |

Three phase four wire |

||

|

Electric control cabinet size |

1300x620x1250 mm |

||

|

Power |

2 rollers 7.5 kw,3 rollers 9 kw, 4 rollers 15 kw,6 rollers 18.5 kw |

||

![]()