Advanced Technology Lithium Battery Recycling Line High Efficiency And Safety

Product Details:

| Place of Origin: | China |

| Brand Name: | TONTEN |

| Model Number: | TT-LDC01 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1SET |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Container |

| Delivery Time: | 15-20 work days |

| Payment Terms: | T/T |

| Supply Ability: | 13 units/month |

|

Detail Information |

|||

| Features: | High Efficiency, Low Energy Consumption, Easy Operation | Material: | Metal/Plastic |

|---|---|---|---|

| Magnetic Field Strength: | 0.8-1.2T | Recovery Rate: | >98% |

| Type: | Battery Recycling Plant | Be Applicable: | Lithium Iron Phosphate Battery |

| Application: | Recycling Of Lithium Batteries | Feature: | Easy Operation; High Seperation Ratio |

| Highlight: | High Efficiency Lithium Battery Recycling Line,Safety Lithium Battery Recycling Line,Advanced Technology Lithium Battery Recycling Line |

||

Product Description

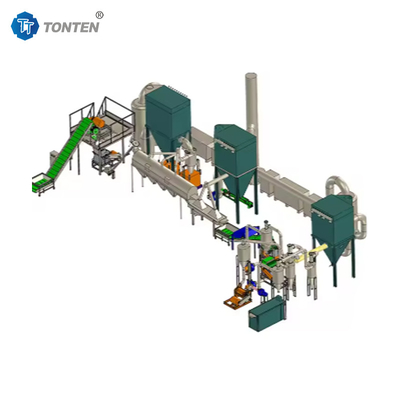

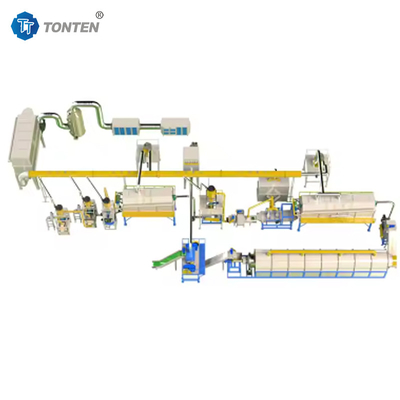

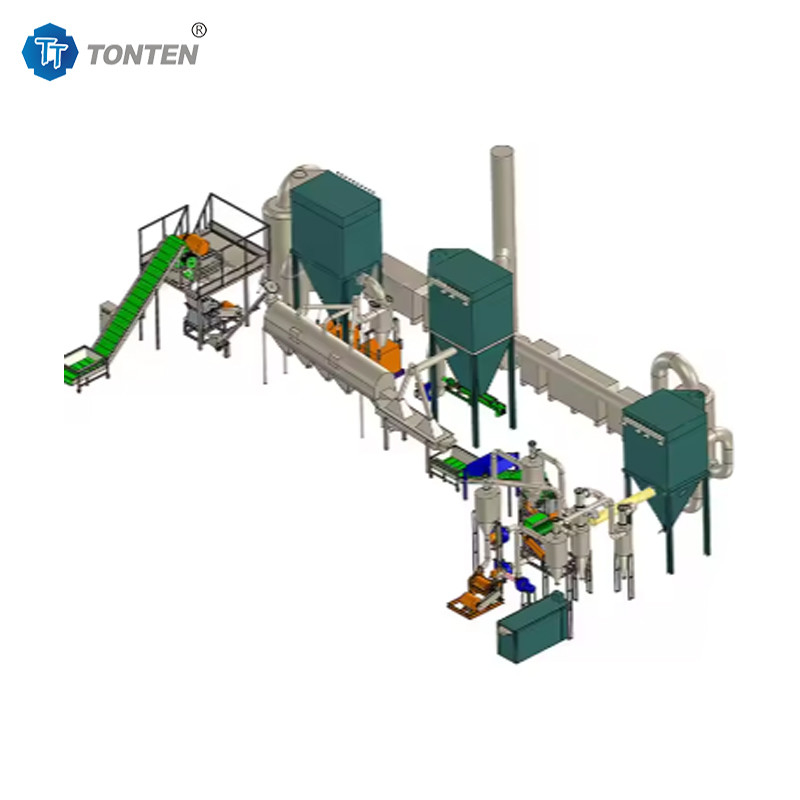

Advanced Technology Lithium Battery Recycling Line High Efficiency and Safety

Product Introduction

Lithium Battery Recycling Production Line is designed to recycle discarded power lithium batteries and small lithium batteries that are abandoned from the production line or no longer usable. It adopts advanced physical crushing and screening processes, abandoning traditional manual and pyrometallurgical treatment methods. This production line features a high degree of automation, with the recovery rate of valuable components in waste lithium batteries exceeding 99% It is capable of handling various types of batteries, such as cylindrical, soft - packed, and square batteries. Not only does it achieve harmless treatment of waste lithium batteries, but it also effectively recycles scarce metals like cobalt, nickel, and lithium, contributing to resource recycling and environmental protection. With the increasing demand for lithium batteries in electric vehicles and electronic products, this production line plays a crucial role in the lithium battery industry cycle, providing a sustainable solution for the treatment of waste batteries.

Product Advantages

Equipped with advanced waste - gas treatment systems (like RTO incinerators and activated - carbon adsorption), ensuring that exhaust gas during the recycling process meets national emission standards, minimizing environmental pollution.

Advanced Processing Technology

Features charged - crushing technology, eliminating the need for cumbersome pre - discharge, thus enhancing processing efficiency. The pyrolysis treatment efficiently decomposes organic matter in lithium batteries under high - temperature and oxygen - deficient conditions, preserving valuable metal components.

Multiple - stage Sorting

Utilizes various physical sorting techniques such as magnetic separation, air - flow sorting, and eddy - current sorting to preliminarily separate metal foils from black powder and other substances, ensuring precise material separation.

Operating Principle

| Model | Power | size | power |

| FJP-1000 | 800-1000kg/h | 81㎡ | 96kw |

| FJP-2000 | 1800-2000kg/h | 81㎡ | 120kw |

| FJP-3000 | 2800-3000kg/h | 81㎡ | 150kw |

![]()