Electric Scrap Copper Wire Recycling Machine Copper Wire Granulator Line

Product Details:

| Place of Origin: | China |

| Brand Name: | TONTEN |

| Model Number: | TT-1000 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 Set |

|---|---|

| Price: | USD 8000/Set |

| Packaging Details: | Small model export wooden packaging, large model load in container |

| Delivery Time: | 10-15 working days |

| Payment Terms: | T/T |

| Supply Ability: | 20 Sets/Month |

|

Detail Information |

|||

| Production Capacity: | 800-1000kg/h | Drive Mode: | Electric |

|---|---|---|---|

| Residual Copper Content: | Very Low | Environmental Performance: | Dry Type, No Dust |

| Automation Level: | Fully Automatic Copper Wire Granulator Line | Motor Type: | National Standard |

| Dust Collection Device: | Equipped With Dust Collection Machine | Discharge Method: | Copper Granulator And Plastic Discharged Different Discharge. |

| Highlight: | Electric Scrap Copper Wire Recycling Machine,Copper Wire Recycling Machine,Copper Wire Granulator Line |

||

Product Description

Electric Scrap Copper Wire Recycling Machine Copper Wire Granulator Line

Basic Overview:

The copper rice machine is a machine used to crush waste copper wires and separate copper from plastics. It is named because the separated copper particles look like rice grains. It is specially used to process various cable wires of various grades such as automotive wires, waste miscellaneous wires, communication cables, and various miscellaneous cables that are not suitable for processing by wire stripping machines. It can completely separate copper and plastics for comprehensive utilization. With the increasing awareness of environmental protection and the increasing importance of recycling waste electronic waste, the copper rice machine can efficiently separate copper and plastics from waste wires, realize resource reuse, and conform to the concept of sustainable development.

Working Principle:

The copper wire granulation production line crushes waste wires and cables through a crusher to make them granular. Using an airflow separator, the copper and plastic particles are initially separated according to the different resistance and gravity they encounter in the airflow. The separation effect can also be further improved by electrostatic separation, and the difference in electrostatic properties of copper and plastic is used to separate them by different forces in the electric field.

Structural Composition:

Feeding device: Feed waste wires and cables evenly into the crusher to ensure a stable supply of materials.

Crushing device: Use high-hardness spindle and tearing tools, such as micro-knife heads and cylindrical knife rods, to crush wires and cables into smaller particles.

Sorting device: Dry types include airflow sorters, air shakers, electrostatic sorters, etc.; wet types are mainly gravity shakers.

Dust collection device: Collect dust generated during crushing and sorting, such as pulse dust collectors, to keep the working environment clean and reduce dust pollution.

Control system: Such as PLC control system, to achieve functions such as uniform feeding, intelligent operation and automatic alarm to ensure stable operation of the equipment.

Performance Characteristics:

1. Environmental protection: Dry copper rice machine has no dust, no secondary pollution, and low noise.

2. High efficiency: It can realize automated production, high production efficiency, can quickly process a large number of waste wires and cables, and improve resource recycling efficiency.

3. Strong adaptability: It can process various types and specifications of waste wires and cables, including automobile circuit lines, motorcycle lines, battery car lines, household appliance lines, communication lines, computer lines, etc., as well as various waste lines that are not suitable for processing by wire stripping machines.

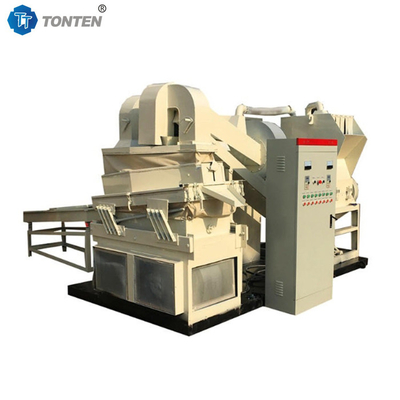

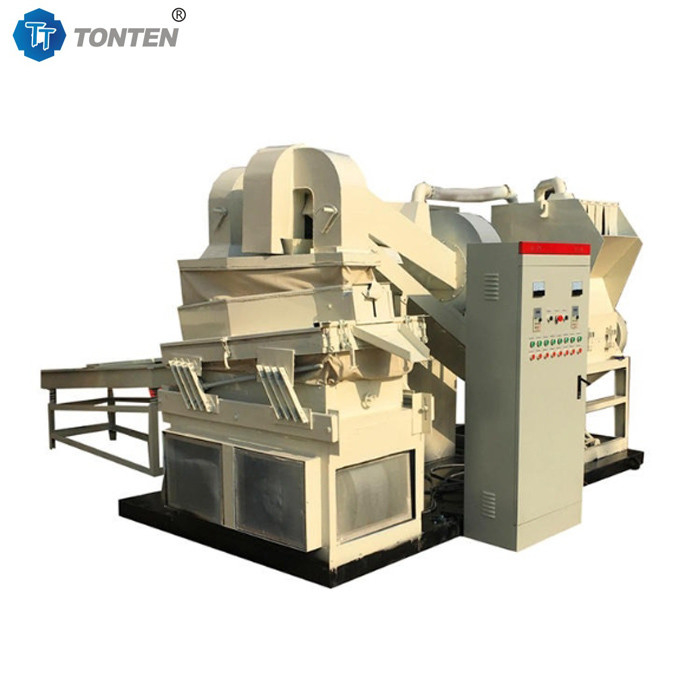

Copper Wire Recycling Line Photo:![]()

Copper Rice Machine Specification:

Machine model | Feed size(mm) | Process capacity(kg/h) | Motor power(kw) | Dimensions(mm) | Weight(kg) |

TTCR-400 | 0.5-40 | 150-200 | 22 | 2600x1600x2300 | 2000 |

TTCR-600 | 0.5-40 | 200-300 | 42 | 3700x2200x2200 | 3200 |

TTCR-800 | 0.5-40 | 300-600 | 57 | 4000x2000x2200 | 3800 |

| TTCR-D800 | 0.5-40 | 400-800 | 85 | 8700x5000x2600 | 4500 |

TTCR-1000 | 0.5-40 | 800-1000 | 97 | 9000x5000x2600 | 5800 |