Factory Sale Simple Operation DF4-35B Brick Machine Hollow Block Making Machine

Product Details:

| Place of Origin: | CHINA |

| Brand Name: | TONTEN |

| Model Number: | DF4-35B |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Wooden box |

| Delivery Time: | 10-15 work days |

| Payment Terms: | T/T |

| Supply Ability: | 20 sets per month |

|

Detail Information |

|||

| Product Name: | DF4-35B Block Molding Machine | Raw Material: | Clay, Mud, Coal Gangue, Shale, Fly Ash |

|---|---|---|---|

| Block Type: | Hollow Paver Solid Interlock Blocks | Molding Cycle: | 40-50s |

| Machine Type: | Automatic | Worker: | 2 |

| Advantage: | High Efficiency | Color: | Customer's Demand |

| Highlight: | Simple Operation Brick Machine,Factory Sale Brick Machine,Hollow Block Making Brick Machine |

||

Product Description

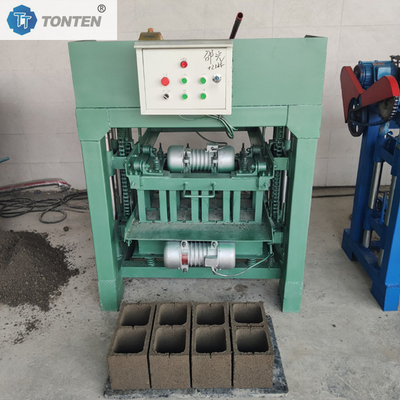

Factory Sale Simple Operation DF4-35B Brick Machine Hollow Block Making Machine

Introduction:

This is 4-35B brick making machine. This brick machine is small, simple easy to use, flexible and can be easily operated by a single person. Mobile design,easy to transfer. After the production is finished, just pull the brick machine to the next working area and you can produce again. The material common to many types of natural building are sand , cement, concrete, etc. Natural building tends to rely on human labor, more than technology. This machine is very affordable for small scale enterprise. In other words, bricks or blocks produced by using this machine are relatively cheap and affordable for those in the rural areas and for low income earners.

Parameter:

| Items | Parameter |

| Molding Type | 35s |

| Equipped with Power | 6.3kw |

| Class is Produced(block) | Standard brick 240*53*115mm 15000

Hollow brick 390*190*190mm 2400

|

| Plate Size(mm) | 850*550*30 |

| Overall Size | Length 1250*Width 1350*Height 1550 |

| The Weight | 800kg |

| Number of Operators | 2-3 |

Product Features:

1.DF4-35B Block Molding Machine adopts four-column guide, is equipped with strong vibration motor, adopts vibration table directional vertical vibration and upper die pressurized vibration, and achieves strong vibration effect with less power, so that each raw material can be vibrated. It can effectively flow and fill densely,greatly improve the production efficiency, and the produced blocks have uniform density and high strength.

2. The machine adopt supper mould push-pull, manual scraping material, and manual take bricks. The operation is convenient and flexible, and it can be quickly mastered.

3. The body is made of large-scale steel and special welding technology and materials, which is strong and shock-resistant. The suspension and connecting parts of the whole machine adopt "spring isolation technology" and directional vertical vibration technology, which reduces power loss, improves compactness, and achieves good performance. The shock absorption effect of the mold also reduces the wear of the mold and prolongs the working life of the mold.

4. One machine is multi-purpose,equipped with different specifications of molds, can produce cement bricks of different

specifications, the mold replacement is convenient and simple, and the maintenance is convenient.

Block Sample:

DF4-35B Block Molding Machine manual paver block machine is suitable for the production of standard bricks, hollow bricks, etc. We can also be customized according to customer needs.

Applicable Materials:

The application of raw materials is extensive , durable and easy to maintain, flexibility. The vulnerable parts can be replaced, not only for maintenance, but also for the cost of mold. DF-35A Block Molding Machine is one kind manual block machine which can produce hollow blocks as well as standard bricks. The materials are usually sand, cement, and stone. The capacity of standard brick is 9000-11000 pieces one day, and the hollow brick is 1500-2000 pieces one day.

Customers:

Our machinery have been widely used in various industries, including mining,recycling,construction material and cement manufacture, chemical industry, electricity, metallurgy, mine, etc., enjoying a good reputation among customers both in the overseas and domestic market. TONTEN Machinery Limited Strictly control the mass production quality and lead time , and let the business goes smoothly !Our Customer Concept: Create Value for customers is the only Reason for Our Existence.

Company Profile:

TONTEN machinery limited always adheres to the service concept of "customer first" and provides customers with a full range of high-quality services. TONTEN has established professional production, R&D and sales departments to serve customers. Future development goals: Comprehensive intelligent manufacturing, realizing automation, informatization and intelligence of the entire production process, improving production efficiency, product quality and resource utilization Providing personalized customization and flexibly adjusting production according to customer needs. R&D team: Committed to continuously optimizing product performance and improving product core competitiveness. Developed a series of stable, reliable and comprehensive mechanical equipment. At the same time, the team closely follows the development of cutting-edge technologies in the industry, continuously carries out product technology research, and injects a steady stream of innovative power into the company. Production team: Strictly abide by the quality management system, implement refined control throughout the production process, and ensure stable and reliable product quality. At the same time, the team is good at using lean production concepts, optimizing production processes, improving resource utilization efficiency, and ensuring that products can be delivered on time and with high quality. After-sales service team: Committed to providing customers with all-round caring support, regularly going to customers' sites for preventive maintenance, in addition, the team also provides customers with technical support services such as operation training and process optimization to ensure the stable operation of customer equipment in all aspects.

FAQ:

1. Who are we?

We are based in Henan, China, start from 2019,sell to Africa(15.00%),Mid East(12.00%),South America(10.00%),South Asia(10.00%),North America(10.00%),Southeast Asia(10.00%),Eastern Asia(10.00%),Domestic Market(8.00%),Northern Europe(8.00%),Central America(5.00%),Oceania(0.80%),Eastern Europe(0.80%),Western Europe(0.30%),Southern Europe(0.10%). There are total about 11-50 people in our office.

2. How can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.What can you buy from us?

Crusher machine,Mining production line,Recycling plastic metal production line,Ball mill,Copper wire recycling machine

4. Why should you buy from us not from other suppliers?

TONTEN machinery limited R&D team,production team, after-sales service team,committed to providing customers with high-quality services,continuously carries out technological innovation and process optimization to create the greatest value for customers.

5. What services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FAS,CIP,FCA,CPT,DEQ,DDP,DDU,Express Delivery,DAF,DES;

Accepted Payment Currency:USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,MoneyGram,Credit Card,PayPal,Western Union,Cash;

Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Hindi,Italian

![]()