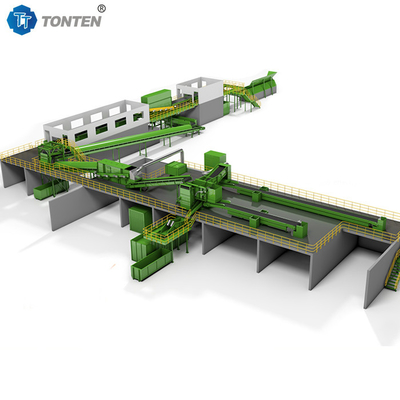

Marble Concrete Pebble Crushing Crusher Recycling Sorting Line

Product Details:

| Place of Origin: | China |

| Brand Name: | TONTEN |

| Model Number: | TT-CW1160 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 Set |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Export wooden packing or in container |

| Delivery Time: | 10-15 work days |

| Payment Terms: | T/T |

| Supply Ability: | 20 Sets per month |

|

Detail Information |

|||

| Metal Recovery Efficiency: | 98% | Mobility: | Fixed / Tire-mounted / Track-mounted |

|---|---|---|---|

| Noise Level: | Install Soundproofing Cover And Vibration Reduction Device | Main Equipment: | Crushing Recycling Sorting |

| Feeding System: | Vibrating Feeder, Plate Feeder | Conveying System: | Belt Conveyor, Chain Conveyor |

| Sorting System: | Iron Remover, Air Separator, Manual Sorting Platform | Recycling Type: | Marble Concrete Pebble Crushing Sorting Line |

| Highlight: | Marble Concrete Pebble Crusher,Marble Concrete Pebble Crushing Line |

||

Product Description

Marble Concrete Pebble Crushing Crusher Recycling Sorting Line

Core components and functions of the crushing recycling line:

1. Crushing system function: crushing large pieces of construction waste (such as concrete beams and columns, wall bricks) to the required particle size.

Main equipment: Jaw crusher: coarse crushing equipment, used to crush materials with high hardness and large volume (such as concrete blocks), the feed particle size can reach 800mm, and the discharge particle size is adjustable from 30-150mm.

Impact crusher / cone crusher: medium and fine crushing equipment. The impact crusher is suitable for crushing medium hardness materials (such as bricks), and the finished product has good particle shape; the cone crusher is suitable for hard materials (such as reinforced concrete) and has strong wear resistance.

Impact crusher (optional): used for sand making, crushing materials to 0-5mm, and producing recycled fine aggregate.

2. Screening system function: classify the crushed materials according to particle size to achieve the separation of recycled aggregates of different specifications.

Main equipment:

Vibrating screen: multi-layer screen (such as 2-4 layers), common model 3YK1860 (processing capacity 100-500 tons/hour), screening efficiency ≥95%, can screen out 0-5mm (fine sand), 5-10mm (coarse sand), 10-30mm (crushed stone) and other multi-grade products.

Drum screen (optional): suitable for materials with high mud content, separating mud and aggregate by rotating the drum.

3. Feeding system Function: evenly convey raw materials to the crusher to avoid blockage and stabilize the production line load.

Main equipment:

Vibrating feeder: model such as ZSW490×110, processing capacity 300-800 tons/hour, with pre-screening function, can screen out mud and fine materials in advance.

Apron feeder (optional): used for stable feeding of large particle size and high hardness materials.

4. Conveying system function: connect various equipment to achieve horizontal or inclined conveying of materials.

Main equipment: Belt conveyor: wear-resistant rubber belt, bandwidth 500-1200mm, conveying speed 1.2-2.5m/s, climbing belt can be configured to adapt to the height difference site.

Chain conveyor (optional): used to convey materials containing steel bars, with strong anti-winding ability.

5. Function of sorting system: remove metal, wood, plastic and other impurities in construction waste to improve the purity of recycled aggregate.

Main equipment: Iron remover: suspended electromagnetic iron remover, removes metal impurities such as steel bars and wires, with a recovery rate of ≥98%.

Air separator: separates light materials such as wood and plastic through airflow, with a sorting efficiency of ≥90%.

Manual sorting platform (auxiliary): manual screening of complex impurities.

6. Environmental protection system Function: control dust, noise and sewage, in line with environmental protection standards.

Main equipment: Dust treatment: bag dust collector, pulse dust collector, dust emission concentration ≤20mg/m³; spray dust suppression device, covering dust-producing points such as crushing and screening.

Noise control: The equipment is equipped with soundproof covers and vibration-damping pads, and the noise level is ≤85dB.

Sewage treatment: Closed-circuit circulating water system, sewage is reused after sedimentation and filtration, and the recycling rate is ≥95%.

![]()

Specification:

|

Model |

Inlet width(mm) |

Motor(kw) |

Discharge size(mm) |

Capacity(t/h) |

|

TT-CW500 |

600 |

37 |

20-50 |

50-80 |

|

TT-CW800 |

1000 |

72 |

20-60 |

80-100 |

|

TT-CW1020 |

1300 |

110 |

30-60 |

100-200 |

|

TT-CW1150 |

1300 |

132 |

30-85 |

200-300 |

|

TT-C1280 |

1600 |

180 |

40-110 |

300-500 |

![]()

![]()