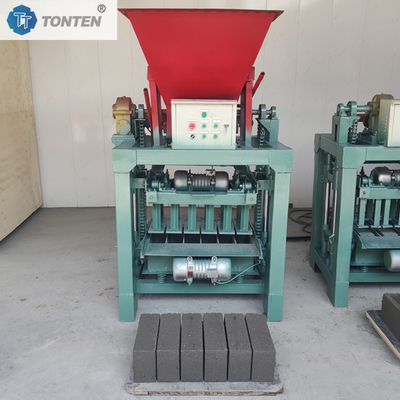

Roadside Stone Molding Machine Concrete Semi-automatic Hollow Brick Making Machine

Product Details:

| Place of Origin: | China |

| Brand Name: | TONTEN |

| Model Number: | DF4-35B |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Wood case packing or customized |

| Delivery Time: | 7-10 days |

| Payment Terms: | T/T |

| Supply Ability: | 1-2 sets about 7-10 days |

|

Detail Information |

|||

| Method: | Hydraulic Pressure | Brick Type: | Hollow Brick Concrete Brick Hole Brick |

|---|---|---|---|

| Operation: | Easy | Quality: | High Quality |

| Main Vibration Form: | Vibration Mode | Core Components: | Engine |

| Marketing Type: | Hot Product 2024 | Port: | Tianjin/Qingdao/Shanghai |

| Highlight: | Roadside Stone Molding Machine,Concrete Hollow Brick Making Machine,Semi-automatic Hollow Brick Making Machine |

||

Product Description

Roadside Stone Molding Machine Concrete Semi-automatic Hollow Brick Making Machine

Paving Block Brick Cement Porous Brick Making Machine is a highly efficient semi-automated machine designed for the production of permeable paving bricks, hollow block bricks and porous cement bricks in block molding machine. Through the hydraulic vibration molding technology and replaceable mold system, different specifications and models of bricks can be manufactured quickly, which is suitable for municipal engineering, landscaping, building walls and other fields.

Concrete Semi-automatic Hollow Brick Making Machine

| Item | Parameters |

| Model | DF4-35B |

| Cycle Time | 30-45s |

| Daily Output | 600 pieces(Determined by brick type) |

| Power | 5.5kw |

| Pressure | 20-35MPa (adjustable) |

| Brick Size | 200x100x60mm to 400x200x150mm (customized) |

| Weight | 720kg |

Concrete Semi-automatic Hollow Brick Making Machine Informations

![]()

Roadside Stone Molding Machine Key Features

Porous and Permeable Design

Equipped with patented porous molds, the brick porosity is as high as 15%-25%, and the water permeability is ≥5mm/s, which meets the demand of sponge city construction.

Highly efficient automated production

Integrated PLC intelligent control system, support one-key operation, production beat can reach 10-15 seconds/block, average daily output of 8,000-20,000 blocks (depending on the model).

Energy saving and environmental protection

Adopting frequency conversion vibration technology, energy consumption is reduced by 30%, noise ≤ 75dB; support the utilization of industrial wastes (e.g. fly ash, slag mixing ratio up to 40%).

High strength and durability

Hydraulic pressure 20-35MPa, brick body compressive strength ≥15MPa, frost resistance (-40 ℃ cycle 50 times without cracking).

Flexible mold system

Quickly change the molds to produce 20+ types of bricks such as chain bricks, hexagonal bricks, grass bricks, hollow blocks, and so on.

Product Advantages

✅ Cost-effective: 40% lower price and 50% less maintenance cost than similar equipment in Europe (modular design).

✅ Multi-purpose machine: produce multiple types of bricks by changing molds, reducing the investment risk of customers.

✅ Environmental protection certification: comply with ISO 14001 environmental management system, support green building projects.

✅ Intelligent monitoring: real-time display of fault codes, remote diagnostic system reduces downtime.

FAQ Customer Frequently Asked Questions

Q: What raw materials are available?

A: We can use sand, stone, cement, and add a lot of fly ash, slag, steel slag, coal gangue, ceramic granules, perlite, wine lees, gypsum powder, feed and other industrial waste materials.

Q: Do I need on-site instruction to install the machine?

A: We provide self-service installation through video guide + 3D manual.

Q: How long is the warranty period?

A: We usually provide one year validity.

Q: Can a machine be used with multiple molds?

A: Depending on the type and size of bricks you need, one machine can be used for multiple purposes.