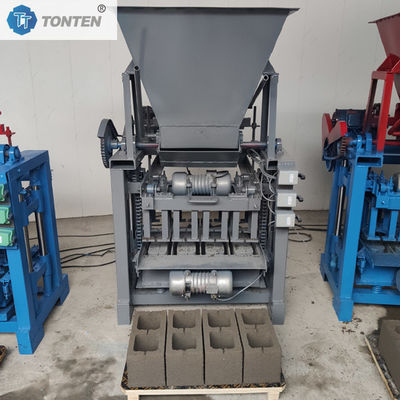

Semi-Automatic Fly Ash Brick Machine Concrete Block Paver Machines

Product Details:

| Place of Origin: | China |

| Brand Name: | TONTEN |

| Model Number: | DF4-26 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 Set |

|---|---|

| Price: | Negotiable |

| Packaging Details: | standard international export packing, container or as required |

| Delivery Time: | 7-10work days |

| Payment Terms: | T/T |

| Supply Ability: | 80 sets per month |

|

Detail Information |

|||

| Features: | High Efficiency | Dimension: | 1680x2040x2500mm |

|---|---|---|---|

| Control Cabinet Dimensions: | 530x300x880mm | Total Power: | 12kw |

| Hopper Size: | 800x760x740mm | Molding Cycle: | 26S |

| Raw: | Fly Ash Concrete | Main Itme: | Semi-Automatic Brick Block Paver Machines |

Product Description

Semi-Automatic Fly Ash Brick Machine Concrete Block Paver Machines

Working Principle:

The 4-26 brick machine operates on a highly automated production process. Its core is a PLC program control system, enabling automatic batching, mixing, molding, and drying. The machine's operation begins with mixing raw materials (such as cement, sand, and fly ash) in a specific ratio. After uniform mixing, the material is fed into the molding machine, where it is pressed into brick blanks under high pressure. Subsequently, the brick blanks undergo curing and drying for a certain period, ultimately becoming finished bricks.The 4-26 brick machine plays a vital role in modern brick production due to its high efficiency, automation, and multi-functionality. It not only improves the production efficiency of building materials but also adapts to the market's increasing focus on environmental protection and quality. Through proper operation and regular maintenance, the 4-26 brick machine can provide continuous and stable support to the construction industry, serving as an important guarantee for achieving efficient and green construction.

Features:

1. Molding System: Presses materials into shape under high pressure, ensuring the density and strength of the bricks.

2. Mixing System: Responsible for uniformly mixing raw materials according to a scientific ratio, ensuring brick quality.

3. Conveying System: Transports the mixture and finished bricks at different stages, equipped with efficient automatic conveying equipment, reducing labor costs.

4. Control System: Employs intelligent PLC control, enabling monitoring and adjustment of the entire production process. Users can easily set production parameters.

5. Electric and Hydraulic System: Provides the necessary power support for the machine, ensuring smoother and more efficient operation.

Applications:

The 4-26 brick machine is suitable for producing a variety of building materials, with a wide range of applications including:

Residential Construction: It can produce hollow bricks, solid bricks, and other building materials in different specifications to meet various construction needs.

Commercial Construction: Due to its high production efficiency, the brick machine is suitable for large-scale commercial building projects.

Infrastructure: The brick machine can also be used to produce paving bricks and masonry materials, supporting infrastructure construction.

Eco-friendly Construction: By using waste materials (such as fly ash and slag) to make bricks, it conforms to the concept of green building.

![]()

Brick making machine specifications:

|

Item |

Specification(LxWxH) |

QTY/Mold(pcs) |

QTY/Hour(pcs) |

QTY/8 Hour(pcs) |

|

Concrete Brick |

400x225x200 400x200x200 400x150x200 400x100x200 |

6 |

480-540 |

3850-4300 |

|

Solid Brick |

240x115x53 240x115x70 |

20 |

2400-3000 |

19200-24000 |

|

Paver Brick |

200x100x60 200x163x60 |

12 |

960-1080 |

7680-8650 |