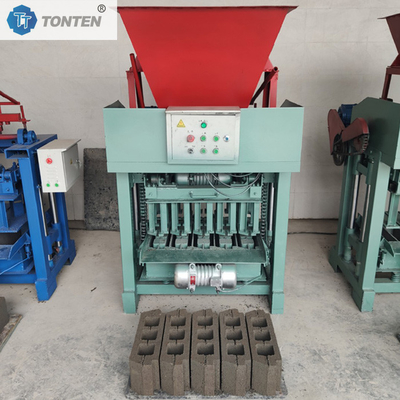

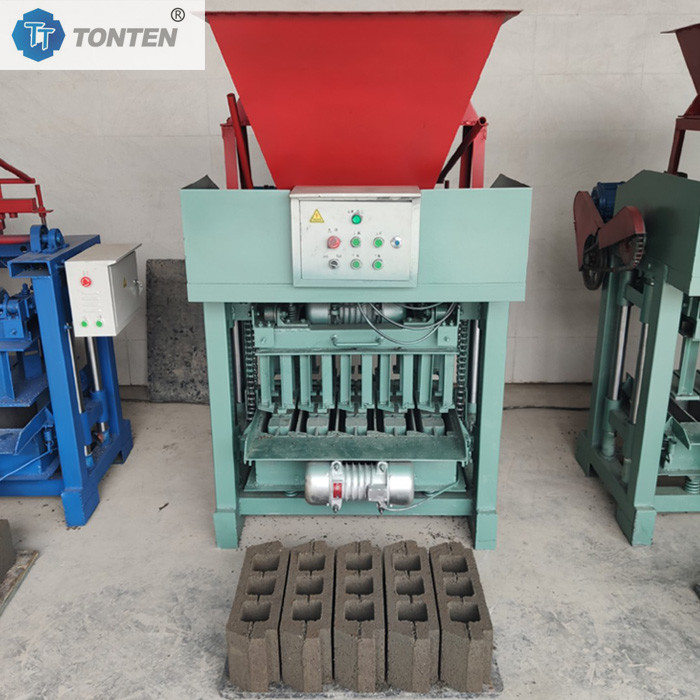

Professional Long-Lasting Brick Machine Adjustable Pressure High Productivity

Product Details:

| Place of Origin: | China |

| Brand Name: | TONTEN |

| Model Number: | TT-DF4-35A |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1SET |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Container |

| Delivery Time: | 5-11 work days |

| Payment Terms: | T/T |

| Supply Ability: | 200 units/month |

|

Detail Information |

|||

| Name: | Block Forming Machine With Hopper | Molding Cycle(s): | 35s |

|---|---|---|---|

| Equipped With Power(kw): | 4.8 | Plate Size (mm): | 850*550*30 |

| Key Selling Points: | Low Price | Automation Level: | Fully Automatic |

| Advantage: | Mobile | Effect: | Good |

| Highlight: | adjustable pressure brick machine,high productivity brick making machine,long-lasting professional brick machine |

||

Product Description

Professional Long-Lasting Brick Machine Adjustable Pressure High Productivity

Product Introduction

The Brick Making Machine we present is a revolutionary device that redefines the brick-making process. It incorporates a self-adjusting raw material proportioning system, which automatically optimizes the blend of ingredients based on preset formulas. The unique rotary forming process replaces traditional linear methods, allowing for continuous and efficient production. The machine is also equipped with a remote control and monitoring function, enabling operators to oversee and adjust production parameters from a distance.

Application Area

In the field of architecture and design, it offers endless possibilities. For luxury villas and high-end apartments, it produces bespoke bricks with intricate patterns and textures, enhancing the elegance and exclusivity of the residences. In the cultural heritage preservation area, it replicates ancient bricks with remarkable accuracy, ensuring the authenticity of historical reconstructions. In the green building movement, it manufactures energy-efficient bricks for sustainable housing projects, contributing to environmental conservation.

Applicable Materials

It can utilize a vast array of materials. Natural materials like basalt and pumice are transformed into bricks with excellent thermal insulation and soundproofing properties. Industrial residues such as coal cinders and waste plastics are recycled, reducing landfill waste and creating value-added products. Additionally, local waste materials like demolition rubble and discarded bricks can be reused, promoting circular economy.

Equipment Advantages

1. Automated Material Proportioning: Saves time and ensures consistent quality by automatically adjusting the raw material mix.

2. Rotary Forming Technology: Enables continuous production, increasing productivity and reducing production cycle time.

3. Remote Monitoring and Control: Provides convenience and flexibility, allowing operators to manage production from anywhere.

4. Customizable Design: Can produce bricks with unique designs and functions, catering to the demands of creative architecture.

5. Sustainable Production: Maximizes the use of waste materials and reduces energy consumption, aligning with environmental goals.

Maintenance And Upkeep

1. Proportioning System Calibration: Regularly calibrate the sensors and actuators of the material proportioning system to ensure accurate ingredient dispensing.

2. Rotary Unit Maintenance: Check the rotary bearings, seals, and drive belts. Replace worn-out components and lubricate as needed.

3. Remote System Check: Test the remote control and monitoring functions, update the app or software if necessary, and ensure network security.

4. Mold Cleaning and Maintenance: Clean the molds thoroughly after each use, check for cracks or deformations, and repair or replace them.

5. General Equipment Inspection: Conduct routine inspections of the entire machine, including electrical, mechanical, and hydraulic systems, to identify and fix potential problems.

Factory Advantages

1. Factory direct sales with sufficient supply. We have our own factory equipment and complete product specifications. We offer one-stop spot purchase to meet your various needs.

2. Customized processing with guaranteed delivery time. We can customize the specifications and sizes according to customer requirements, and ship on time according to the delivery time.

3. Selling at factory price to save costs. Manufacturer's source of goods, eliminating intermediary price differences and cost savings, spot delivery, win-win cooperation.

We pursue low profit and high turnover, and we can offer you a lower price than other trading companies. We will make every effort to meet the needs of our customers and provide efficient and high-quality Brick Making Machines. If the product is truly suitable and can benefit you, the price can be negotiated. Please call or contact us through other means for further discussion. We are based on integrity and prioritize quality. Our machines are manufactured strictly in accordance with national and international standards, and we test each device before delivery.

Parameter Table

| Model | Name | Class is produced (block) |

Overall size (mm) |

Weight (kg) |

Number of poerators |

| DF-DMB | DF-Diesel moving brick machine | Standard brick 240*53*115mm 3600pcs Hollow brick 390*190*190mm 600pcs |

1900*1000*1550 | 250 | 1-2worker |

| DF4-35A | Block molding machine | Standard brick 240*53*115mm 15000pcs Hollow brick 390*190*190mm 2400pcs |

1250*1350*1550 | 750 | 2-3worker |

| DF4-35A | Block forming machine with hopper | Standard brick 240*53*115mm 20000pcs Hollow brick 390*190*190mm 3200pcs |

1200*1280*1950 | 780 | 2-3worker |

![]()

![]()