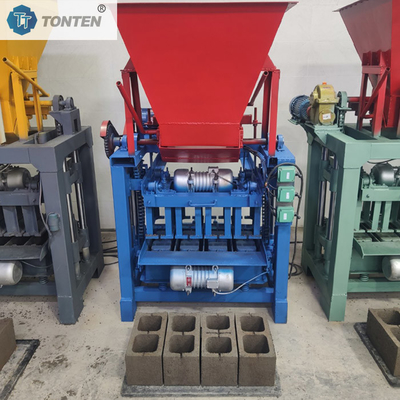

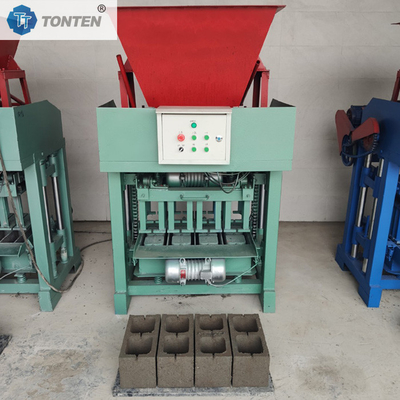

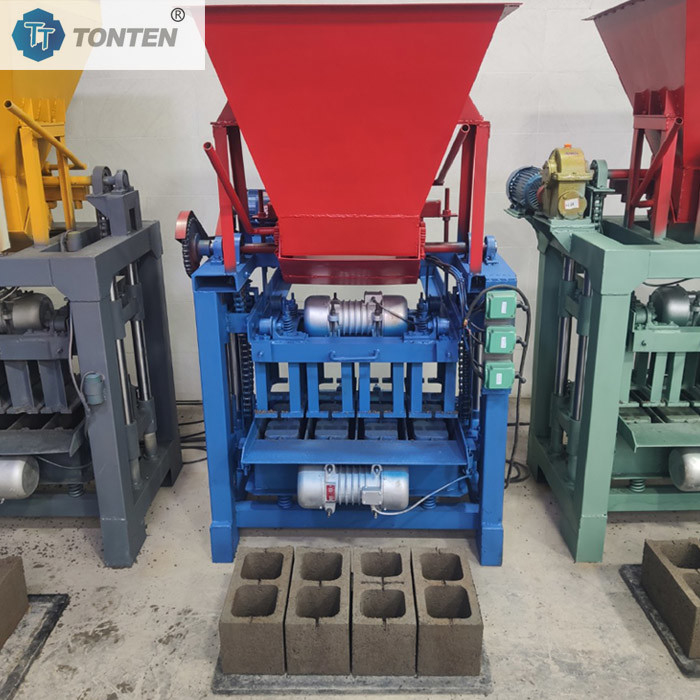

Premium Adaptable Brick Making Machine Control Excellent Material Compatibility

Product Details:

| Place of Origin: | China |

| Brand Name: | TONTEN |

| Model Number: | TT-DF4-35B |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1SET |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Container |

| Delivery Time: | 5-11 work days |

| Payment Terms: | T/T |

| Supply Ability: | 200 units/month |

|

Detail Information |

|||

| Marketing Type: | New Product 2025 | Style: | Modern |

|---|---|---|---|

| Advantage: | Mobile | Quality: | High Quality |

| Molding Cycle(s): | 35s | Equipped With Power(kw): | 6.3 |

| Plate Size (mm): | 850*550*30 | Number Of Poerators: | 2-3worker |

| Highlight: | adaptable brick making machine,brick making machine with material compatibility,premium brick making machine control |

||

Product Description

Premium Adaptable Brick Making Machine Control Excellent Material Compatibility

Product Introduction

Our Brick Making Machine is a high-performance piece of equipment designed to meet the evolving needs of the brick-making industry. It features a modular raw material preparation system, which allows for easy addition or replacement of processing modules. The innovative pneumatic forming system applies uniform pressure through air compression, resulting in bricks with a uniform and smooth texture. The machine is also equipped with an augmented reality (AR) assisted maintenance guide, which provides visual instructions for technicians during repairs and maintenance.

Application Area

In the construction of public transportation facilities, it is indispensable. For subway stations, railway platforms, and bus terminals, it manufactures bricks that can withstand heavy foot traffic and harsh weather conditions. In the field of education and research, it produces bricks for laboratories and classrooms, meeting the requirements of safety and functionality. In the tourism industry, it creates bricks for historical monuments and tourist attractions, preserving the cultural heritage and enhancing the visitor experience.

Applicable Materials

It has wide applicability when it comes to raw materials. Clay and shale, the staples of brick making, are processed to produce reliable and durable bricks. Industrial by-products like ferrochrome slag and nickel slag are recycled, reducing the environmental burden and cost. Even some natural fibers like flax can be added to produce bricks with improved flexibility and insulation properties.

Equipment Advantages

1. Modular Design: Facilitates customization and upgrades, allowing users to adapt the machine to changing production requirements.

2. Pneumatic Forming Technology: Produces bricks with a superior texture and quality, enhancing the market competitiveness of the products.

3. AR Assisted Maintenance: Reduces maintenance time and errors, making it easier for technicians to keep the machine in top condition.

4. High Durability: Built with high-quality materials and advanced manufacturing techniques, ensuring a long service life.

5. Wide Material Compatibility: Can work with a variety of materials, providing more options for product innovation.

Maintenance And Upkeep

1. Modular System Check: Inspect each module of the raw material preparation system, clean the filters and ducts, and replace any malfunctioning modules.

2. Pneumatic System Maintenance: Check the air compressors, valves, and pneumatic cylinders. Tighten loose connections and replace damaged seals.

3. AR Maintenance Guide Update: Keep the AR software up to date, add new maintenance procedures if necessary, and ensure the device compatibility.

4. General Cleaning: Clean the exterior and interior of the machine, remove any debris or dirt that could affect performance.

5. Regular Inspection: Conduct regular inspections of all mechanical, electrical, and hydraulic systems, and address any issues promptly.

Factory Advantages

1. Factory direct sales with sufficient supply. We have our own factory equipment and complete product specifications. We offer one-stop spot purchase to meet your various needs.

2. Customized processing with guaranteed delivery time. We can customize the specifications and sizes according to customer requirements, and ship on time according to the delivery time.

3. Selling at factory price to save costs. Manufacturer's source of goods, eliminating intermediary price differences and cost savings, spot delivery, win-win cooperation.

We pursue low profit and high turnover, and we can offer you a lower price than other trading companies. We will make every effort to meet the needs of our customers and provide efficient and high-quality Brick Making Machines. If the product is truly suitable and can benefit you, the price can be negotiated. Please call or contact us through other means for further discussion. We are based on integrity and prioritize quality. Our machines are manufactured strictly in accordance with national and international standards, and we test each device before delivery.

Parameter Table

| Model | Name | Molding cycle(s) |

Equipped with power(kw) |

Class is produced (block) |

Overall size (mm) |

| DF4-35B | Block molding machine | 35s | 6.3 | Standard brick 240*53*115mm 15000pcs Hollow brick 390*190*190mm 2400pcs |

1250*1350*1550 |

| DF4-35B | Block forming machine with hopper | 35s | 6.3 | Standard brick 240*53*115mm 20000pcs Hollow brick 390*190*190mm 3200pcs |

1200*1280*1950 |

| DF4-40A | Block molding machine | 35s | 7.5 | Standard brick 240*53*115mm 20000pcs Hollow brick 390*190*190mm 3200pcs |

1500*1300*1800 |

| DF4-40A | Hopper brick block machine | 35s | 7.5 | Standard brick 240*53*115mm 24000pcs Hollow brick 390*190*190mm 3600pcs |

1600*1300*2300 |

![]()

![]()