Semi-automatic Block Molding Machine PLC Control System Brick Machine

Product Details:

| Place of Origin: | China |

| Brand Name: | TONTEN |

| Model Number: | 4-35B |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Wooden box packaging |

| Delivery Time: | 10 days |

| Payment Terms: | T/T |

| Supply Ability: | 1-2 sets about 7-10 days |

|

Detail Information |

|||

| Port: | Qingdao/Shanghai/Tianjin/Dalian | Operation Method: | Semi Automatic |

|---|---|---|---|

| Voltage: | 220V / 380V | Effect: | Good Quality |

| Type: | Vibration Molding | Main Vibration Form: | Vibration Mode |

| Suit For: | Cement Pavement | Material: | Cement / Concrete |

| Highlight: | PLC Control System Brick Machine,Semi-automatic Brick Machine,Block Molding Machine |

||

Product Description

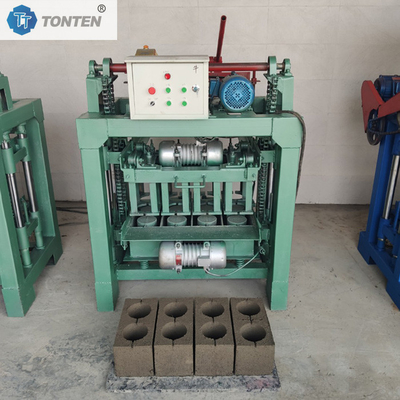

Semi-automatic Block Molding Machine PLC Control System Brick Machine

The 4-35B semi-automatic block molding machine is designed to produce various types of concrete or clay blocks with a combination of manual and automated processes. The manual process is designed to be operated by a manual lever and the automatic process is designed to be operated by a PLC controlled electrical box for better operation of the machine to produce various types of blocks smoothly.

Block Molding Machine Usage:

①Producing various kinds of hollow blocks:

such as wall blocks, partition blocks, heat preservation blocks, colorful pavement bricks, etc.

② Apply to small construction projects:

such as residential, commercial and infrastructure, small plants, warehouses and so on.

③ DIY projects:

small investment, quick return, favored by small builders and craftsmen, can be used in various construction and landscaping projects.

PLC Control System Brick Machine

| Model type | 4-35B |

| Molding cycle | 35s |

| Overall size | 1250*1350*1550mm |

| Weight | 800kg |

| Number of operators | 2-3 person |

| Class production |

Standard brick 15000 pieces 240*53*115mm |

PLC Control System Brick Machine

![]()

Block Molding Machine Features:

①Semi-Automated Operation:

Combines manual input with automated functions, such as mixing, molding, and demolding, enhancing efficiency.

②Versatile Molding Options:

Capable of producing different block types, including solid, hollow, and interlocking blocks, using interchangeable molds.

③Hydraulic System:

Many models use hydraulic pressure for compacting the material, which improves the density and strength of the blocks.

④User-Friendly Controls:

Equipped with simple operating panels, making it easier for operators to manage the production process.

⑤Durable Design:

Constructed from robust materials to ensure longevity and withstand the rigors of continuous use.

Block Molding Machine Advantages:

① Cost-effective: the price is more affordable compared to fully automatic equipment, and the investment cost is lower.

② Easy to operate: easy for workers to learn and operate, only need to watch the video to get started.

③ Convenient maintenance: the structure of the brick machine is simple, the maintenance cost is relatively low.

④ Strong adaptability: it can produce a variety of specifications and shapes of hollow blocks to meet the diversified needs of customers.

FAQ

Q: How to choose the right machinery products?

A: According to your specific needs, such as production scale, product type, budget, etc., choose the right product model and specification.

Q: How to operate the machinery products correctly?

A: We will send machine operation video for viewing, if you have any questions, please contact after-sales service personnel.

Q:How to maintain and care for the mechanical products?

A: Regular cleaning, lubrication and inspection, timely replacement of wearing parts to extend the product life.